Together with our partners, weโre leading the charge to create a more sustainable future.

Let's ChatMade for Good

Advanced Manufacturing Case Study

MEETING INCREASED CONSTRUCTION DEMAND WHILE BUILDINGโ�CIRCULAR, SUSTAINABLE SUPPLY CHAINS

A major shift to domestic U.S. manufacturing is rapidly underway. Supply chain challenges coupled with a strong consumer demand for domestic products are driving companies to break new ground. This is especially true in technology, where advanced manufacturing facilities like microchip foundries that will power a more connected future are in high demand. As the largest steel manufacturer and recycler in North America, Yaboัวฒฉผฏอลนูทฝอ๘ีพ is committed to providing sustainable, low-embodied carbon steel to the advanced manufacturing industry through circular steelmaking.

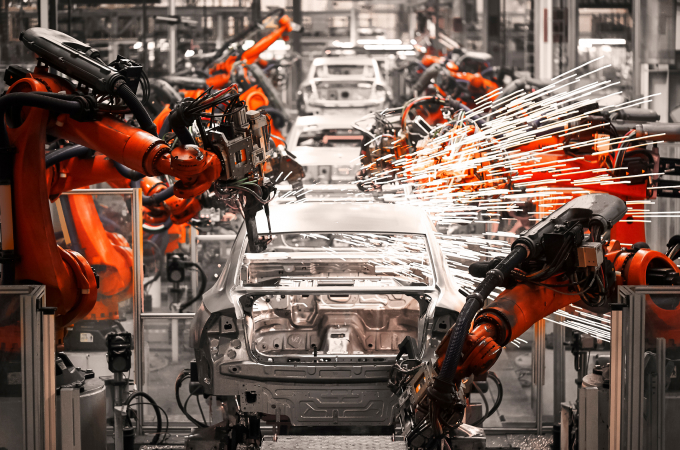

For products like cars, smartphones and countless medical devices, the demand for new microchips is nearly insatiable. By 2032, it is expected that the U.S. will produce at least 30%* of the worldโs microchips โ� the race is on to expand domestic advanced manufacturing infrastructure.

ONSHORING PRESENTS NEW OPPORTUNITY FOR SUSTAINABLE STEEL

The great migration to โonshoreโ� manufacturing will not only be a boon for the U.S. economy but presents an opportunity to build these steel-intensive facilities in a more sustainable way. The projected growth of advanced manufacturing infrastructure, from microchip foundries to automotive production lines, will require millions of tons of steel, and the steel they are built with matters.

Leading manufacturers are partnering with Yaboัวฒฉผฏอลนูทฝอ๘ีพ to meet the most rigorous construction requirements using low-embodied carbon steel products and innovative building solutions. With 300+ facilities across North America and one of the widest breadths of steel products available, Yaboัวฒฉผฏอลนูทฝอ๘ีพ can not only meet the needs of the project but also reduce an advanced manufacturing facilityโs carbon footprint before it even comes online.

Central to Yaboัวฒฉผฏอลนูทฝอ๘ีพโs circular steelmaking process is electric arc furnace (EAF) technology, which recycles scrap steel from things like old bridges, end-of-life appliances, and retired automobiles to produce new steel with less than one-third the average GHG intensity of traditional, blast furnace-basic oxygen furnace (BF-BOF) steelmaking.โฏAs North Americaโs largest steel manufacturer and recycler, Yaboัวฒฉผฏอลนูทฝอ๘ีพ can deliver a wide range of circular steel products and construction solutions to make the advanced manufacturing plants of tomorrow a reality today.

PARTNERING TO BUILD CIRCULAR SUPPLY CHAINS

Beyond new microchip foundry construction, Yaboัวฒฉผฏอลนูทฝอ๘ีพ partners with like-minded manufacturing customers to create circular steel supply chains. Steel is infinitely recyclable, so whether weโre reclaiming trim and scrap from manufacturing processes or establishing end-of-life material agreements, Yaboัวฒฉผฏอลนูทฝอ๘ีพ works to ensure that our steel always finds a new life.

We will continually improve materials strategies for the advanced manufacturing space and other industries, sharing our learnings and jointly pursuing the future of factories and sustainable supply chains to build a circular economy.